REMAINING COMPETITIVE IN THE 4TH INDUSTRIAL REVOLUTION

In the midst of the 4th Industrial Revolution (4IR), humanity is facing huge economic, social and environmental changes. Consumers also have evolving expectations regarding the quality, cost and sustainability of products. Accordingly, the companies manufacturing these goods require flexibility and agility throughout the supply chain.

Competing in this setting requires supply chain resilience and line retention through seamless, agile, collaborative and reliable processes. As machinery and production processes are being revolutionized, optimizing the S2P cycle should get equal attention. Streamlining supply chains enables industrial equipment manufacturers to focus resources on the strategic areas of their business.

BOLSTERING YOUR PROCESSES

As the machinery and production processes become increasingly connected and automated, so should the procurement process for supplies and materials. Esker’s AI-based cloud platform will:

- IMPROVE THE CUSTOMER SERVICE EXPERIENCE

by streamlining the order processing to vendors to help meet customer fulfillment requirements

- Minimize payment disputes and errors

by cutting down on manual input and implementing automated workflows and streamlining internal exchanges

- Reduce payment periods

and the ability to negotiate discounts with suppliers

- Offer a great user experience

due to a single, platform-wide interface

Paul Hartwig | Production Director | Firstan

Read full story >

STRENGTHENING SUPPLIER RELATIONSHIPS

Since industrial equipment manufacturers inhabit an intermediary role in the production chain of goods, reliably having everything they need available is essential. Also, equipment is expensive, so manufacturers need to be cost-effective elsewhere. Esker’s 22P solution supports this need by helping companies:

- Consistently deliver accurate, on-time supplier payments

- Avoid blocked orders thanks to rapid dispute resolutions and real-time communication tools

- Provide real-time visibility into invoice approvals and payment status

- Offer suppliers the choice of how to transmit documents

- Simplify invoice creation with flip PO capabilities

REDUCING THE ENVIRONMENTAL FOOTPRINT

Both consumer demand and noticeable climate change are pushing businesses away from focusing entirely on reducing costs to building sustainable supply chains and minimizing their carbon footprint.

Automating the S2P cycle enables a business to:

- Reduce paperand office equipment use

- Develop a sustainablebusiness model by choosing ethical and environmental partnerships

- Optimize energyuse with a cloud-based platform

- Reduce carbon footprintwith Esker’s commitment to environmental standards (EcoVadis Gold Medal, ISO14001 certification)

Andrew Phillips │ Accounting Manager │ Parts Town

Read full story >

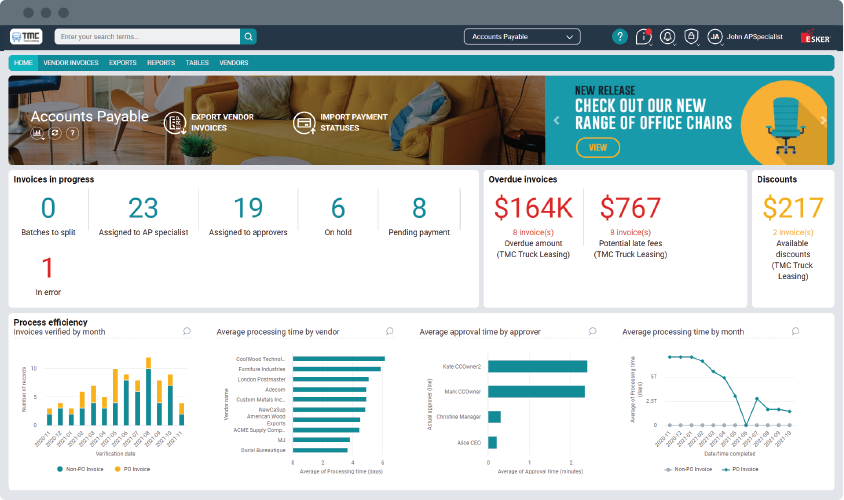

EMPOWERING YOUR TEAM WITH DATA

Esker facilitates collaboration and improves visibility within the manufacturing and distribution functions of industrial equipment companies by providing valuable process information, including:

- Real-time tracking and reporting for financial staff

- Increased visibility and traceability at all levels through electronic workflow

- Standardized AP invoice processing across the enterprise

- Eliminate manual data entry with OCR technology

- Customized dashboards for individualized workflows

Ask us anything

Esker experts are always here to answer any question or provide more info.